Army Organizations Partner to Get Rapid Water Screening Test in the Hands of Soldiers

Access to safe drinking water is critical for maintaining the health and strength of deployed Soldiers. Despite this requirement, water testing technologies currently available to Soldiers in the field are limited in their ability to detect a broad array of industrial contaminants. U.S. Army Center for Environmental Health Research scientists recognize this gap in technology and are collaborating with small businesses to develop a robust portable monitoring system capable of detecting a wide range of industrial chemicals and environmental contaminants.

While a good start, this effort only solves part of the problem. In order to be used by Soldiers working in forward areas, the monitoring system needs to be rugged, low maintenance and easy to operate.

USACEHR researchers are teaming up with staff from the U.S. Army Medical Materiel Development Activity to further refine the system. The opportunity arose April 14 to test recent modifications to the equipment where Soldiers from the 1st Area Medical Laboratory in Aberdeen, Maryland, were recruited to test the equipment out at Fort Detrick, Maryland.

The Environmental Sentinel Biomonitor is a broad-spectrum screening system that can detect whether drinking water is potentially toxic. The ESB is comprised of two separate water toxicity tests: an electric cell-substrate impedance sensor, or ECIS, and a sensor that uses enzymes to detect pesticides. The systems are used in tandem and testing takes less than one hour to complete.

The USACEHR collaborated with small business technology firms to adopt both systems to the ESB. The testing by the 1st AML was done to assess the performance of the ECIS, which had undergone a minor upgrade to improve field performance.

ECIS technology is a non-invasive biophysical method to monitor living cells in vitro. Researchers grow cells on small biochips surfaced with a gold film containing electrodes. When testing water samples, technicians place the biochips in a reader that sends an electrical signal through the chip. If the water sample does not contain contaminants, the cell layer on the chip is resilient and able to impede the flow of electricity. If the water is contaminated, the cell layer becomes damaged and breaks apart. The system monitors these cellular responses with software that allows users to determine whether the sample is toxic. A contaminated or not contaminated result is given within an hour.

Mark Widder, a USACHER research biologist, explained that their small business partner, Nanohmics, Inc., initially developed an ECIS technology that used mammalian cells. While the equipment worked, the system was large and complicated as mammalian cells required extensive care.

"The cells needed to be maintained at 37 degrees centigrade, they required carbon dioxide and had to be fed regularly," explained Linda Brennan, a USACEHR research biologist. "The technology just wasn't field ready."

The team decided on a cell line originally harvested from the gills of rainbow trout after experimenting with a number of cell types.

"The fish have a unique physiology. Because they are cold-blooded, their metabolism slows down even more when refrigerated," said Widder. "When we refrigerate the biochips containing the fish cells we only have to feed them twice and then the chips can stay refrigerated up to nine months and be instantly ready for testing when removed from cold conditions."

Having refined the science behind the ECIS sensor, USACEHR researchers have turned their attention to ensuring the product is appropriately tailored for military use, relying upon USAMMDA's expertise in advanced development.

"We had the rainbow trout gill cells, we had the chip and prototype, but we needed to make it field ready," said Alan Harner, a product manager with the Medical Support Systems Project Management office at the USAMMDA.

The joint Army-contractor team made enhancements to the ECIS sensor, such as inserting a previously external battery pack inside the carrier and making it more compact and durable. They tested all product enhancements to confirm that the monitor worked as designed. When updated modeling data was loaded onto ECIS system equipment, the team called in the people whose job it is to collect and analyze samples from the environment to evaluate system performance - preventive medicine specialists from the 1st AML.

"For me, having the Soldiers conduct the testing is invaluable. They are the ones that will be using the technology," said Widder. "We are making sure it works in their hands so they have the ability to make sure the water is safe in the field."

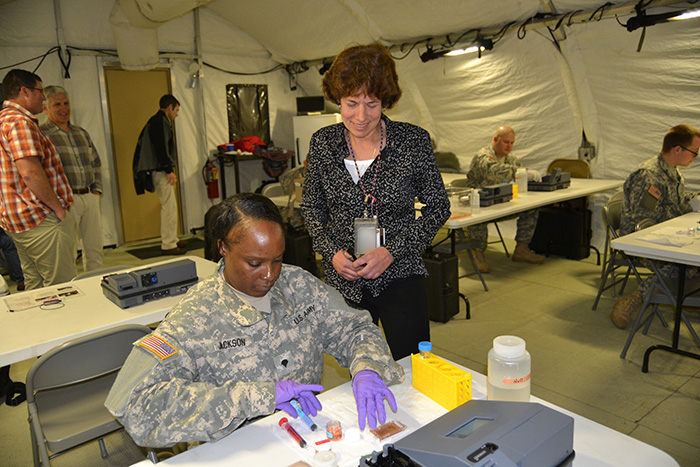

To ensure test integrity, the team worked with Ginn White of the Army Institute of Public Health, Drinking Water and Sanitation Program to serve as an observer/controller. Working with blind samples distributed by White, the 1st AML Soldiers conducted tests in simulated field conditions provided by the Air Force Medical Evaluation Support Activity at Fort Detrick.

Spc. LaToya Jackson, a preventive medicine specialist with the 1st AML and product tester, weighed in on her experience working with the system and said, "I actually like it. It's easy to use and straight-forward."

Pvt. Matthew Arnold, also with the 1st AML, echoed Jackson's sentiments as he progressed through the test.

"Getting used to any piece of equipment is weird at first," said Arnold. "It should be very easy to use - all the instructions are simple and laid out."

According to Brennan, the ECIS sensors performed "flawlessly" during the day's testing. All control samples were identified as not contaminated and spiked samples were identified as contaminated.

With this round of field-testing now completed, the USACEHR and USAMMDA will prepare for product production and fielding, which is the next ESB acquisition milestone.

An official website of the United States government

An official website of the United States government

) or https:// means you've safely connected to the .mil website. Share sensitive information only on official, secure websites.

) or https:// means you've safely connected to the .mil website. Share sensitive information only on official, secure websites.